July 11, 2024

Ryan S. Brandenberg/Temple University

Ryan S. Brandenberg/Temple University

A skin substitute developed by bioengineers at Temple University could be a breakthrough in wound care, pending its approval by the FDA. The technology uses soy proteins and it could change how burns, bed sores, diabetic foot ulcers and other wounds are treated.

When he was 10 years old, Joseph Connell was burned on 30% of his body. His leg was so severely damaged the wound went down to the bone, and doctors told him he would never walk again. Connell had 360 skin grafts, leaving new wounds where the healthy tissue once was. Three times a day during his six-months hospital stay, nurses squeezed Dakin's solution, a mixture of water, baking soda and chlorine bleach, from a turkey baster onto the gauze on Connell's injuries to prevent infection.

"That's something you never forget, and I never will," Connell said. "You have this horrible, horrendous scar that at the age of 10 left you susceptible to a lot of teasing and ribbing. You lived with it, hoped it would fade, and it didn't."

Connell built himself back up to become a high school wrestler and has had a successful career in pharmaceutical and biotechnology sales, marketing and executive management. But his childhood experience drove him to give up a salary 14 years ago to help a group of bioengineers, now at Temple University, develop the first plant-based skin substitute and treatment that they hope transforms the landscape of wound care.

Other skin substitutes on the market for treating chronic wounds are made from human or animal tissue or secretion sources. But through electrospinning – a method used in the textile industry after World War I to make nylons – the Temple bioengineers have produced a nanofibrous wound dressing from soy protein for burns, bed sores, diabetic foot ulcers and other wounds, to help heal and regenerate healthy skin. Because it has a long shelf-life and does not need refrigeration, this treatment could be valuable in countries with limited medical care, military settings and street medicine, Connell said.

The U.S. Food and Drug Administration still needs to approve the plant-based substitute skin, which it considers to be "more like a fancy Band-Aid than a medicine." That categorization should speed up the process, said Jonathan Gerstenhaber, an assistant professor of bioengineering at Temple who is among the scientists working on the project.

Connell anticipates FDA approval by the end of the year, at which point Temple will begin human trials in its podiatry department, since approximately 15% of people with diabetes have foot ulcers that can become infected and sometimes lead to amputation.

The inspiration for this innovative wound care treatment was sparked while Peter Lelkes, chair of Temple's bioengineering department, was visiting China more than a decade ago. Eating Yuba, made from curdled soybeans, Lelkes noticed that its dried membrane resembled the skin-like matrices his team was trying to produce back in Philadelphia.

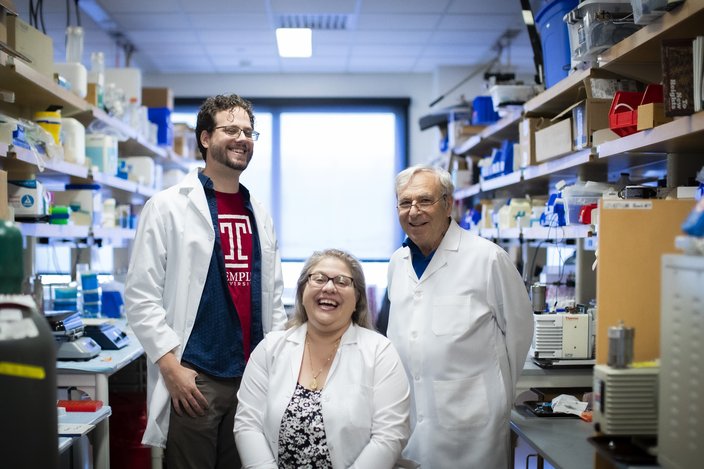

Temple University bioengineers Jonathan Gerstenhaber, Yah-el Har-el and Peter Lelkes have been developing a soy-based wound treatment for over a decade. Anticipating FDA approval by the end of the year, it will be the first plant-based skin replacement for wound care.

"I brought some of the stuff (home) with me and went into the lab and said, 'Look, guys, I think we have something unique here that we can make scaffolds from,'" Lelkes said. "Their first reaction was, 'Get the heck out of here.' So they actually, literally threw me out. But I'm perseverant."

Biological scaffolds provide the mechanical anchors upon which new tissues can grow, just as construction scaffolds provide primary frameworks for buildings.

In studies with rats and pigs, the researchers found that the skin substitute's soy proteins acted as a scaffold that enabled the skin to heal "... to the point that it was much closer to what our normal skin is like under the surface," said Yah-el Har-el, an associate professor of bioengineering at Temple. "And that's good, because when we're talking about the wounds that would potentially be treated with this, they're large, full-thickness wounds, and typically you don't get a full reemergence of healthy tissue when these types of wounds heal. What's on the market now isn't capable of having hairs grow once the tissue heals, of having sweat glands come back after the tissue has healed. But what we found with the pig studies is that we did see that with our treated dressing. We did see new hair follicles and new glands."

The natural protein cells interact with the electrospun soy-based matrices so that "... when the cells are starting to regenerate, they're able to do it in a more appropriate way," Gerstenhaber said. "And so it's really about allowing the body to heal itself …"

The soy-protein treatment comes in the form of skin substitute patches which can be woven with antimicrobials and antifungals. Or, a health care professional can dispense a liquid form of the treatment directly onto wounds with a special device, without having contact with the patient.

"As a burn victim, I will tell you, you don't want anything to touch your raw burned leg, not a nurse, not a bandage and certainly not Clorox," Connell said.

Antimicrobials and antifungals can also be added to the liquid form of the substitute skin, and researchers at Carnegie Mellon University in Pittsburgh are studying how to incorporate stem cells into the liquid wound treatment, Connell said.

The first research funding the team received was a $50,000 grant from the United Soybean Board. "So farmers helped the scientists," said Connell.

They've been working on a "shoe-string budget" ever since, he said, and they've been looking for a manufacturer to come on board. No matter what, Connell said, "I won't give up ... This isn't a job. It's a mission, and that's the big thing."

Ryan S. Brandenberg/Temple University

Ryan S. Brandenberg/Temple University